CNC machining

Focusing on fields such as medical, semiconductor, aviation, energy, automotive, and communication.

Provide precision parts machining, five axis linkage parts machining, complex parts machining,machining of Inwa alloy parts, titanium alloy parts machining, engineering plastic parts machining, stainless steel parts machining, and non standard parts machining.

Obtained:

ISO9001:2015

ISO13485:2016 certification

Provide CNC machining services on demand

For new products and customers, confirm the machining process plan based on different industry requirements and material conditions, prepare process documents, and determine the machining process flow; Select the most suitable production equipment for different parts to achieve the most efficient production efficiency; On site CNC process debugging to solve on-site machining process problems; Improve existing processes or fixtures to enhance production efficiency and product quality; Design practical and efficient tooling fixtures, and conduct audits, certifications, and final product acceptance of outsourced tooling fixture design schemes; At the same time, we will provide professional advice to customers in different fields based on our rich CNC professional knowledge combined with our company's high-end high-precision equipment. Especially for non professional customers, we have repeatedly suggested to achieve the effect of saving costs and accelerating sample progress for customers. And received unanimous praise.

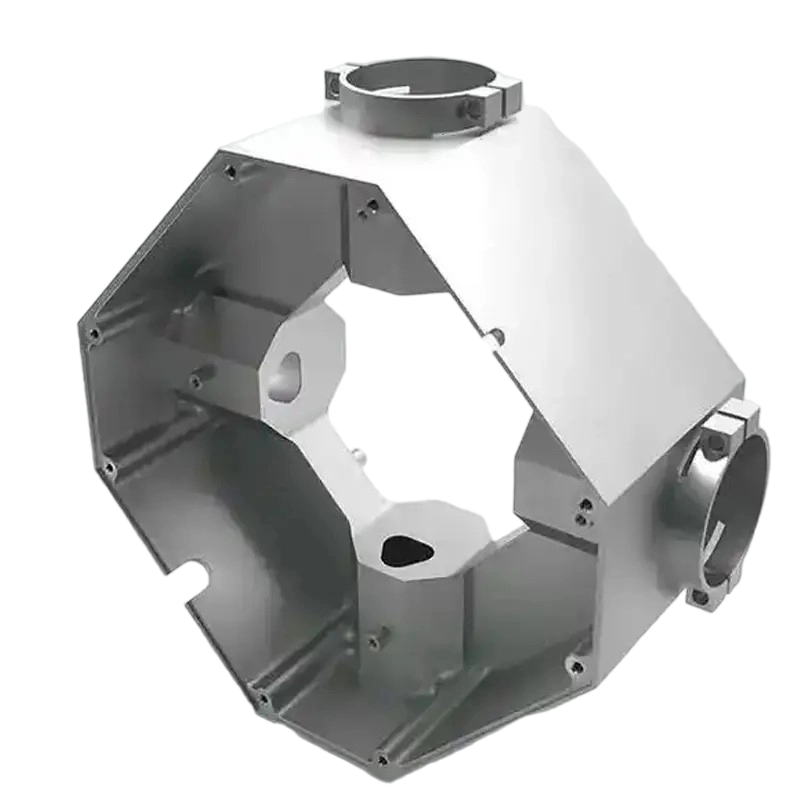

Product Display

Be good at precision machining,mass production.

CNC machining materials and surface treatment

Stainless steel series (316/316L/316F/303/304/420, etc.), aluminum alloy series (AL6061/5083/7075/2A12, etc.), alloy series (Invar alloy, cobalt nickel alloy, 718, etc.), engineering plastic series (PEEK/POM/ABS/PTFE, etc.), glass fiber series (G10/FR4, etc.), carbon fiber series, copper material series (C1100/black copper, brass, tin bronze, etc.)Aluminum Processing Series:aluminum cnc service,cnc aluminum,aluminum machining,cnc aluminum cutting,aluminium cnc machining,aluminum cnc machining service,cnc aluminum parts,machined aluminum parts,aluminum machining service,aluminum cnc machining service.Copper processing series:copper machining,machining copper,peek cnc machining,ptfe cnc machining,brass cnc machining,alloy cnc machining.Metal processing series:metal cnc,metal cnc machining,metal machining,cnc machining metal,custom cnc metal,cnc metalworking,cnc metal processing,cnc metal,5 axis metal cnc.

The above materials are all the expertise and experience of our company, which can select different cutting tools and create different processing programs according to different materials.

Surface treatment: a complete set of high-quality surface treatment processes.

Gold plating, silver plating, tin plating, nickel plating, chromium plating, oxidation, sandblasting, screen printing, laser engraving, electroless nickel deposition, spraying, chemical cleaning, vacuum packaging, heat treatment, wire drawing, passivation, chelating salts, conductive oxidation, powder coating, conductive paint, etc.

Precision machining capability

While investing heavily in high-end production equipment and introducing multiple high-end testing devices, sumitech has a clearer understanding that the long-term development of the enterprise requires a sound management system. Under the ISO9001 and ISO13485 quality and management system standards, sumitech strives to provide customers with complete and traceable services.

FAQ

There is no minimum quantity! Sumitech provides single Precision parts processing and mass production services.

3D drawings, 2D drawings, PDF format, Supports all file formats, welcome to inquire.

Precision machining tolerances as low as ±0.002inches (0.005mm), complete drawing required tolerances.

According to the time of your order, achieve on time delivery.

Provide demand

We can achieve your idea